Packaging Printing Software

From rigid to flexible, food to pharmaceutical, PrintVis understands, addresses and resolves the unique challenges of the packaging printing industry.

Manufacturers of food and beverage packaging, folding cartons, labels, wraps and all other commercial packaging types face multiple challenges as their clients seek ever-more creative ways to attract consumers to their product. Read ePac’s story here.

While the end user may frequently discard the outer packaging without a second thought, PrintVis understands the painstaking lengths to which packaging companies must go to satisfy their customers, and the many planning hours and complexities associated with each production run.

PrintVis packaging solution is built on the engine of Microsoft Dynamics 365 Business Central, and can act as quality control assurance from the earliest stages of the job by putting all the relevant data at the fingertips of those who need it.

PrintVis will make your packaging company run smarter, more streamlined, and empower you to capture the data you need to optimize your business internally, which will help you to impress and retain your customers.

A Complete Solution for Packaging Printing Companies

From the estimating stage to pre-production and the many stops on the shop floor, or outside vendor, through which a folding carton or any other type of custom printed packaging typically goes before finally landing on a store shelf, packaging houses understand there is very little room for error if a job is to remain profitable. One overlooked knockout at the UV coater can waste an entire position at the fold/glue stage, leading to potential job shortages, extra material costs, re-runs and, in such cases as the pharmaceutical industry, more serious liabilities which can threaten the very life of your packaging company. Quality control is especially important for packaging manufacturers

Packaging printing companies must pay particular attention to shipping weights, environmentally-friendly materials (such as vegetable-based inks and recycled papers), tensile strengths of their products, as well as temperature sensitivity, and much more.

The need for waste reduction, cost management over raw materials, effective measurement of performance, and the maintenance of a profitable and innovative operation are paramount.

Whether with short, custom digital runs or large/bulk factory runs, paper board packaging can be managed from quote to invoice with an intelligent print management information system. When that system is built on a proven ERP system, printers can manage every aspect of their businesses with a single software solution.

PrintVis provides quality control assurance by giving you control and insight into every stage of your production. PrintVis will make your company run smarter and more efficiently, empowering your people to capture the data needed to optimize your operation, which will help you to satisfy, retain and grow your customer base.

See how PrintVis’ features can bring value to your packaging business? Book a demo to get your tailored introduction to PrintVis.

JDF Integration and the ESKO Automation Engine

JDF (Job Definition Format) certification offers cross-platform, common integration and process automation, answering the simple question, “What should one common job ticket for the print industry look like?” With JDF, print companies have a single common language to support the entire life cycle of a job.

In common commercial printing, a standard JDF workflow is made for a fully integrated production order, where all production processes – from layout work in prepress to the packing of the final product – are included.

However, workflows for the packaging and label industries often differ because the process starts with a separate prepress order. Packaging industries work with what we refer to as Finished Good items. These are defined products which are reordered and produced in the same way repeatedly. This means the prepress workflow is a generic process and a perfect opportunity for automation via the ESKO Automation Engine.

PrintVis continues to develop our integration with the ESKO Automation Engine as packaging companies around the world are leveraging digitization to optimize workflows and standardize processes.

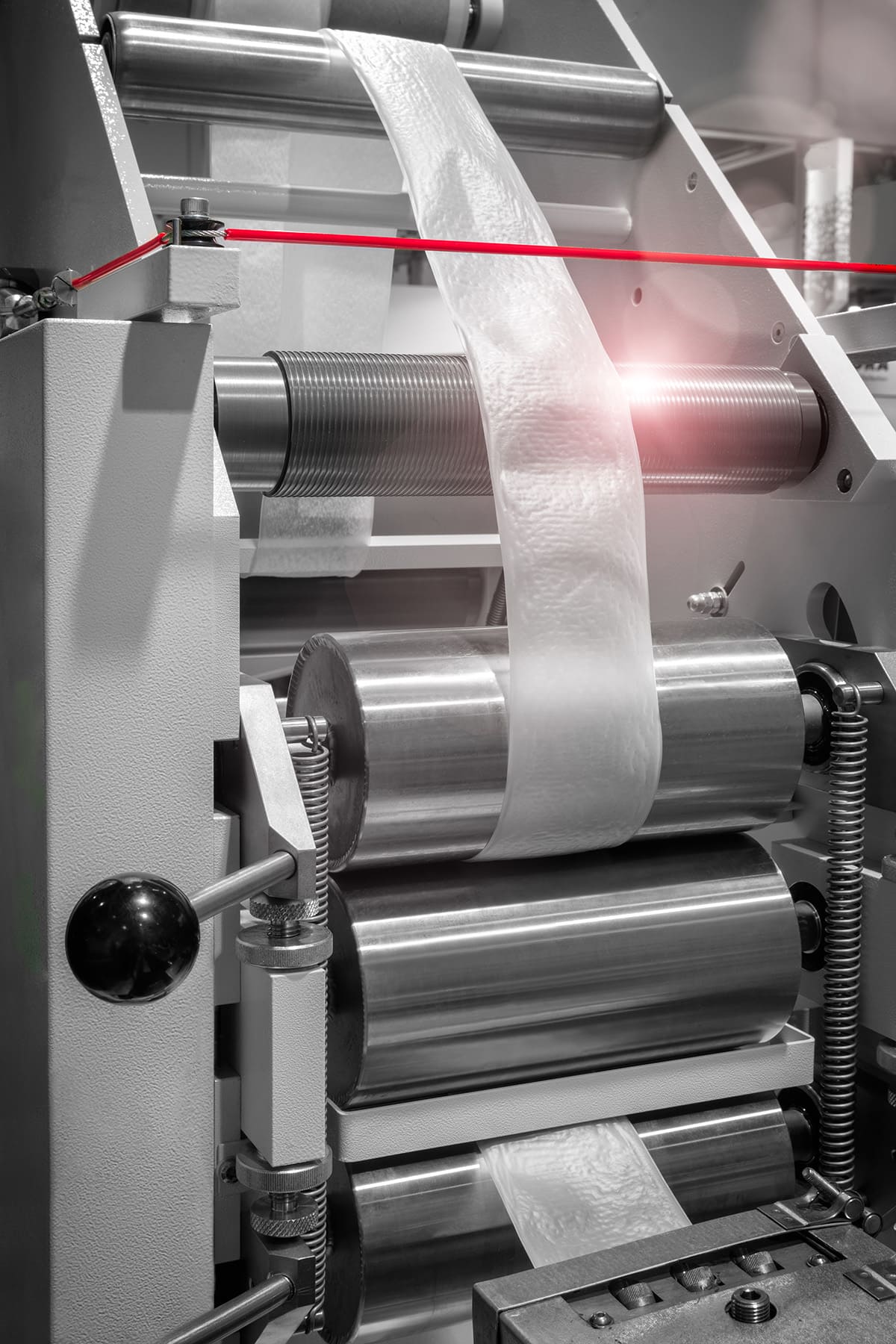

Flexible Packaging Software

PrintVis’ functionalities are a perfect fit for the flexography industry, which dedicates most of its output to flexible packaging.

You can decide (per machine) to produce stated quantities – or to calculate the quantity you expect per full roll of substrate produced (this is especially important to large-format flexo print, such as printing the outer wraps for corrugated boxes.

- If your business has a single, large-format flexo printer it can be set to always produce full reels of substrate

- Other smaller flexo stations can be set to print specific quantities, utilizing only portions of the reels per order

- The specific information on which exact flexible relief plates (clichés) and inks/ink quantities that goes into each specific product – using Finished Goods templates

- Large flexo printers will often have an on-site color lab, so the ability to handle ink recipes is also covered by PrintVis

How PrintVis Will Help Your Packaging Company

- Thorough management of your production materials, including plates, rollers, inks, coatings and adhesives

- Quickly determine if a carton/box is in stock and issue a production order if not

- Produce more than ordered, put the remainder on inventory, invoice the ordered quantity

- Plan multiple shipments of goods on future dates on the same order. Invoice now or as shipped

- Import your die layout and display this on the shop floor screens

- Store layouts of finished goods for future use

- Manage and pick dies (house dies or customer owned) in a searchable library

- Purchase dies for special jobs and add the cost to the job costing

- Manage life cycles for dies (impression counts)

- Manage customer-finished goods or standard box items in variations (e.g. Mint/Chamomile/Orange Spice Tea variants of the same box size in same order)

- Manage batches of same finished good (e.g. pharmaceutical industry cartons or items) and track which orders produced them

- Reruns of orders with different quantities on variations.

- Production scheduling with independent tools (move between machines)

- Quality assurance steps/questions to control production process with stop-function if required

- SLA (service-level agreement) and SLA reporting possibility per customer or per finished goods item if required

- Coatings and required knockouts

- Die-cutting

- Folding & Gluing

- Finishing – such as foil stamping, embossing, tip-ins and more